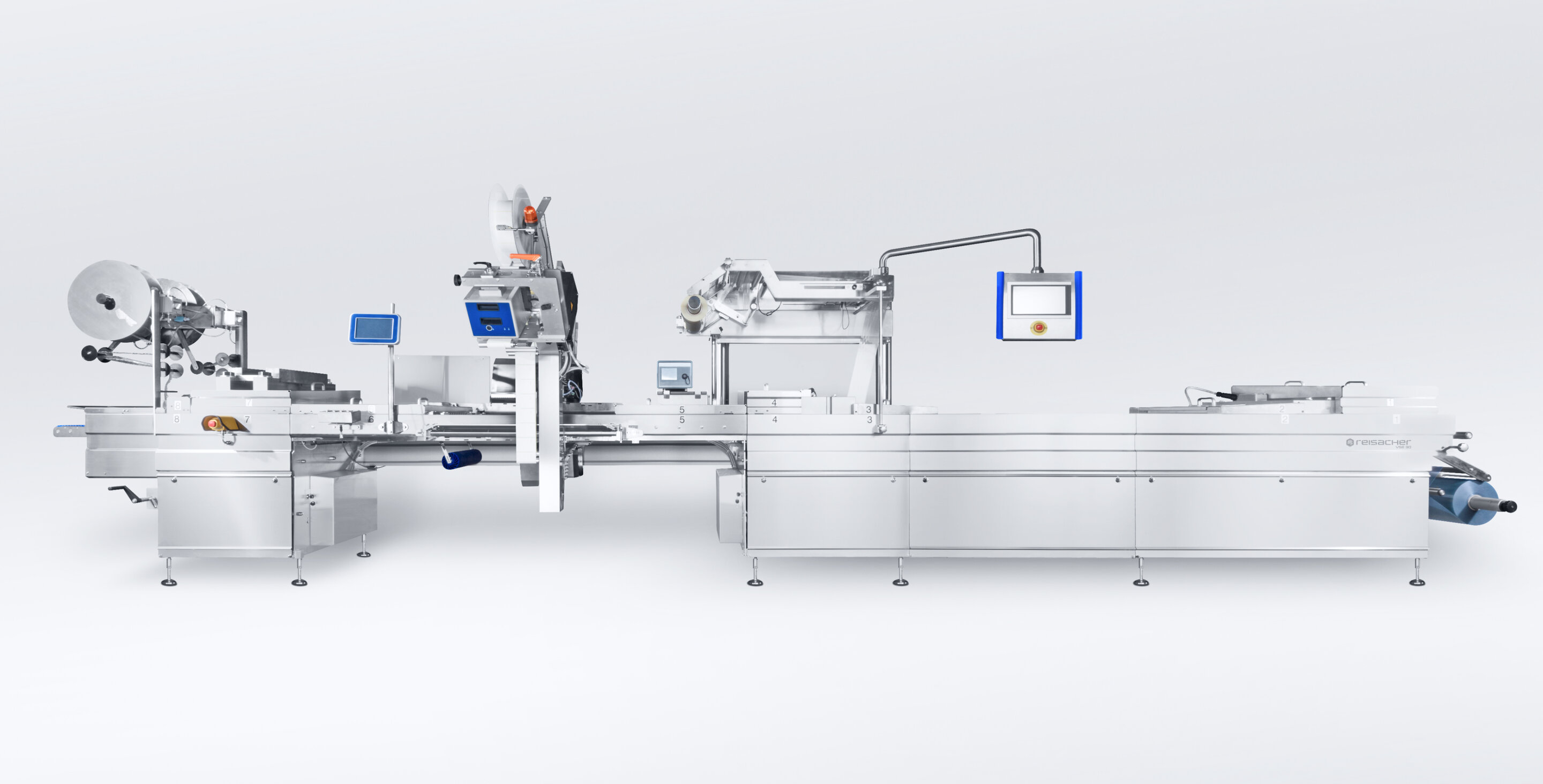

Thermoforming packaging machine

VSE30

reisacher-VSE30 thermoforming packaging machine - the innovative solution for your packaging needs. With its sophisticated hygienic design, user-friendliness and flexibility, it sets new standards. The VSE30 offers optimum support for the operator, minimises technical downtimes and enables efficient cleaning. With a great variety of modular designed modules, powerful software and intelligent safety and sensor technology functions, it is perfectly tailored to your individual requirements. The hygienic stainless steel design, easy film change and various cutting systems offer maximum product and process reliability. Discover the wide range of applications for this reliable and hygienic solution in the packaging industry, from meat and sausage products, cheese, fruit and vegetables to medical and industrial products.

reisacher VSE30 - Innovative packaging solution

The reisacher VSE30 thermoforming packaging machine is an innovative solution that impresses with its well thought-out hygienic design, user-friendliness and flexibility.

The most important features and advantages at a glance:

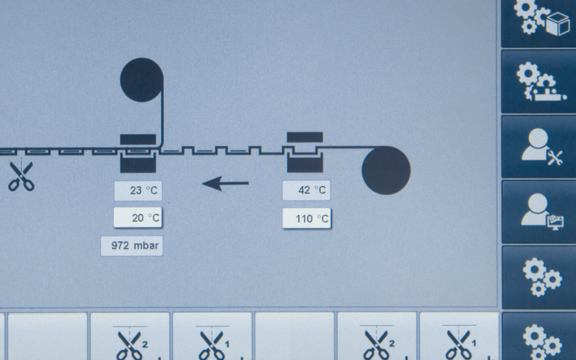

- Operator and service orientation: the VSE30 offers optimum operator support and maximum process reliability. With simple mechanics, high-end software and sensor technology, technical downtimes are minimised and efficient cleaning is made possible.

- Design: The machine is equipped with modular designed modules. The control cabinet has powerful software and sensor technology as well as an intelligent safety shutdown. The touch-screen panel on a swivelling arm offers a user-friendly operating philosophy and extensive diagnostic options.

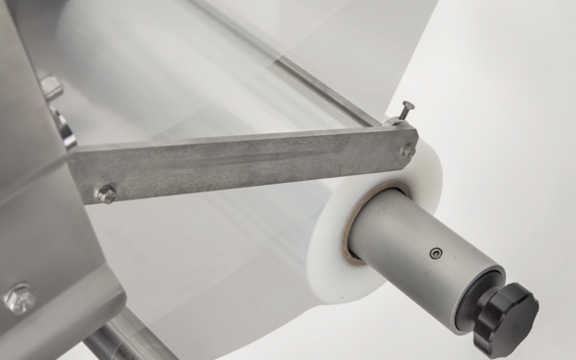

- Film change: The film change has been optimised and simplified to minimise time and effort.

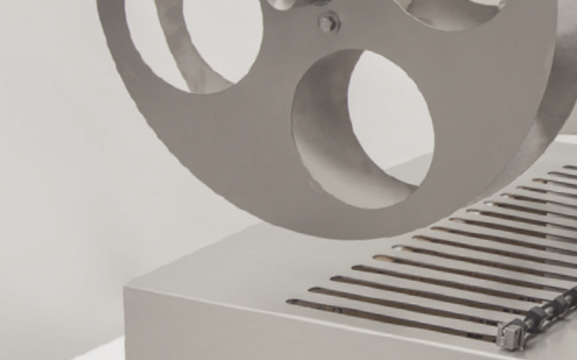

- Cutting systems: The VSE30 offers various cutting systems to create customised packaging solutions.

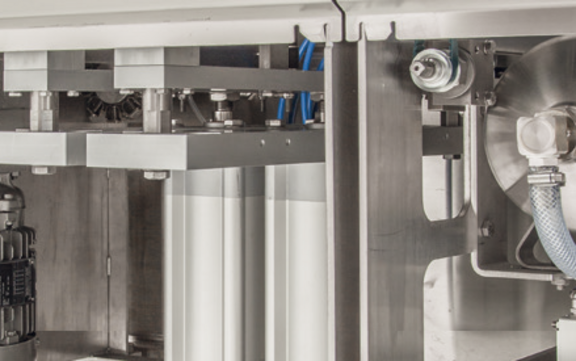

- Hygienic design: The machine is made of a stainless steel construction that meets the latest hygiene requirements. The machine frame and side panels are easily removable or hinged for easy cleaning. The welded modules are robust, rigid and easy to clean.

With the reisacher VSE30 thermoforming packaging machine, customers get a reliable and efficient solution that ensures the highest product and process safety. The flexibility of the modular design allows individual configuration according to the customer's specific requirements. The hygienic design, simple operation and optimised processes make the VSE30 a sustainable and hygienic solution for the packaging industry.

reisacher VSE30 - flexibility and modular assembly concept

The reisacher VSE30 is further characterised by its high flexibility and modular designed modules:

- Machine length: variable depending on machine configuration

- Nominal machine width: From 285 mm to 620 mm (special widths available on request)

- Cut-off length: 200 mm - 600 mm

- Drawing depth: Up to 150 mm

- Output: Up to 15 cycles per minute

- Film: The used material, printing, diameter (maximum 400 mm), and core size can be customized (standard: bottom - 3" core, top - 3" core, optional 6").

Thanks to the modular design of the VSE30, it can be flexibly configured to meet customers' individual requirements. From machine width to cut-off length to film specification, every aspect can be adapted to specific needs. This enables a tailor-made solution for each customer and optimum use of the available production space. With the reisacher VSE30, customers not only get maximum flexibility, but also the highest efficiency and quality in thermoforming packaging for their products.

- Flexible modular design

- Individual designed modules

- High product and process reliability

- Efficient cleaning and maintenance

- Optimisation of the packaging process

- Future-oriented solution for the packaging industry

- Maximum flexibility in thermoform packaging

- Highest efficiency and quality

- Customised solution for individual requirements

- Optimum use of production space

GENERAL DATA

| Features | Values |

|---|---|

| Machine length | Depending on machine configuration |

| Nominal machine width (mm) | 285 - 320 - 355 - 420 - 459 - 520 - 560 - 620 |

| Special widths | available on request |

| Index length (mm) | 200-600 |

| Forming depth (mm) | ≤ 150 |

| Performance | ≤ 15 cycles /min. |

INFORMATION ON THE FILM

| Film | Material | Printed | Diameter (mm) | Core |

|---|---|---|---|---|

| bottom | flexible, semi-rigid | option | ≤ 400 | 3" |

| top | flexible, semi-rigid | option | ≤ 400 | 3" |

EQUIPMENT

| Features | Values |

|---|---|

| Voltage | 3 x 400 V 50 Hz - with neutral wire and protective conductor |

| Compressed air (bar) | 6-10 |

| Cooling water (bar) | 1,5 - 4,5 |

OUTSTANDING FEATURES

| Features | Values |

|---|---|

| DISCHARGE CONVEYOR | Standardised and customised discharge or separation systems |

| CONTROL CABINET |

|

| TOUCH-SCREEN PANEL ON SWIVELLING ARM |

|

| FILM CHANGE | Optimised and simple film change |

| CUTTING SYSTEMS | For customised special packages |

| SEALING |

|

| HYGIENIC DESIGN |

|

POSSIBLE SEALING VARIANTS AND OPENING AIDS

| Sealing solutions | Description |

|---|---|

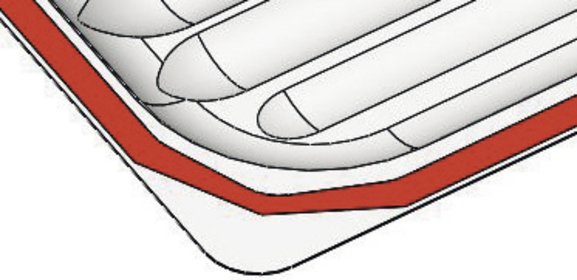

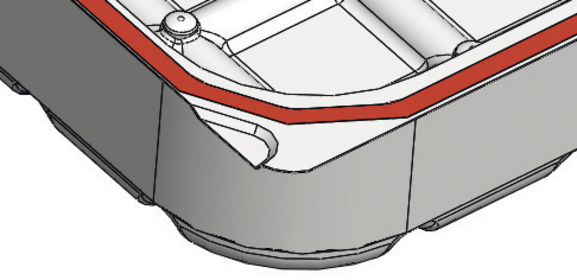

| Peel corner | Easy opening of packages through loose/unsealed upper film tab. The customised sealing seam is set back slightly. |

| Tear-open tab | Easy opening of a package through a loose/unsealed tear-open tab running over the entire width of the package. |

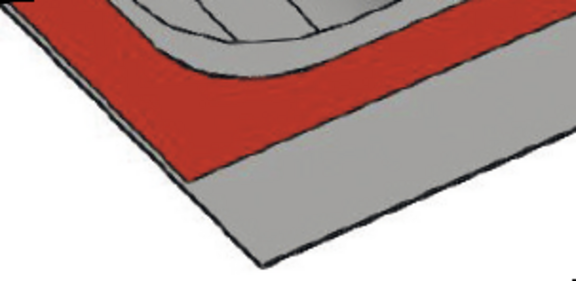

| Peel corner with bottom web deformation | Reaching in or under the upper film makes opening of packages easier. The customised sealing seam is set back slightly. |

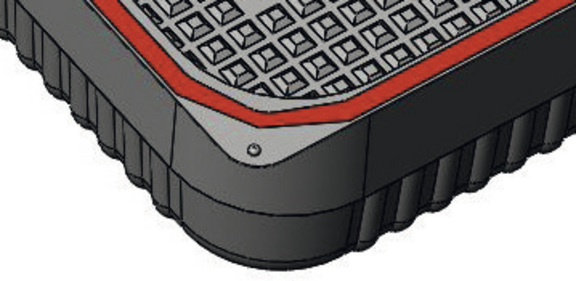

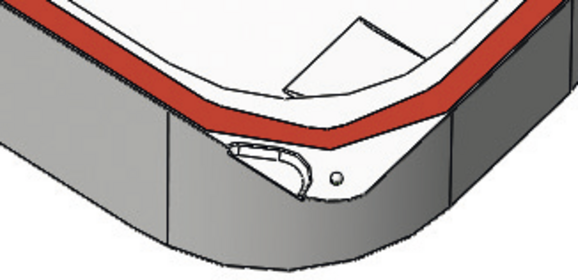

| Bottom film corner cut | The corner section of the bottom film is sealed with the upper film at selected points. During opening, the bottom foil supports opening through better grip of the corner. |

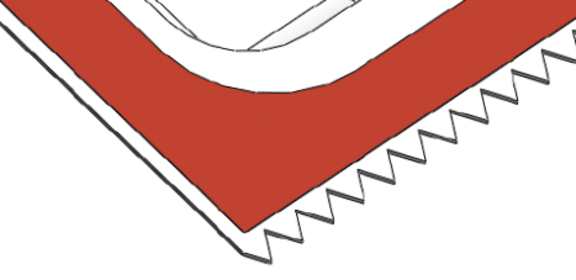

| Jagged cut | Easy tearing or tearing open of the package at the jags. |

STANDARDEasy opening of packages through loose/unsealed upper film tab. The customised sealing seam is set back slightly.

STANDARDEasy opening of packages through loose/unsealed upper film tab. The customised sealing seam is set back slightly. WITH RAISED BUMPS

WITH RAISED BUMPS STANDARDEasy opening of a package through a loose/unsealed tear-open tab running over the entire width of the package.

STANDARDEasy opening of a package through a loose/unsealed tear-open tab running over the entire width of the package. STANDARDReaching in or under the upper film makes opening of packages easier. The customised sealing seam is set back slightly.

STANDARDReaching in or under the upper film makes opening of packages easier. The customised sealing seam is set back slightly. WITH RAISED BUMPSReaching in or under the upper foil makes opening of packages easier. To further improved opening of packages, raised bumps support the lifting of the unsealed upper film. The customised sealing seam is also set back slightly.

WITH RAISED BUMPSReaching in or under the upper foil makes opening of packages easier. To further improved opening of packages, raised bumps support the lifting of the unsealed upper film. The customised sealing seam is also set back slightly. SPECIAL APPLICATIONSCustomer-specific requirements in the opening aid area, incl. the sealing seam are possible.

SPECIAL APPLICATIONSCustomer-specific requirements in the opening aid area, incl. the sealing seam are possible. SKIN APPLICATIONThe corner section of the bottom film is sealed with the upper film. During opening, the bottom film supports opening through better grip of the corner. Suitable for skin applications.

SKIN APPLICATIONThe corner section of the bottom film is sealed with the upper film. During opening, the bottom film supports opening through better grip of the corner. Suitable for skin applications. STANDARDThe corner section of the bottom film is sealed with the upper film at selected points. During opening, the bottom foil supports opening through better grip of the corner.

STANDARDThe corner section of the bottom film is sealed with the upper film at selected points. During opening, the bottom foil supports opening through better grip of the corner. STANDARDEasy tearing or tearing open of the package at the jags.

STANDARDEasy tearing or tearing open of the package at the jags.