Computerslicer CCS 602 A 200

MPS 3 Control

Lenze Drive

High performance Slicer for slicing meat, sausage and cheese

products into slices with adjustable thickness of 0,1 to 50 mm.

The sliced portions are transported by the transfer-unit CCU,

consisting of portioning conveyor and a control conveyor.

Machine control system with user-friendly interface.

Machine made completely of solid stainless steel.

Product carrier 602 B 10.30.10.000

Carrier unit for product length up to 1,200 mm.

Product support belt. The support belt moves forwards up to the slicing bar

after the loading procedure. At the end of each slicing procedure the support

belt is pulled back pneumatically and in this way clears an opening for the

ejection of the end pieces. The conveyor belt runs synchronously with the

gripper by which it is driven. The support conveyor and the conveyor belt can

be removed from the machine.

including end piece ejection flap,

execution ground and polished.

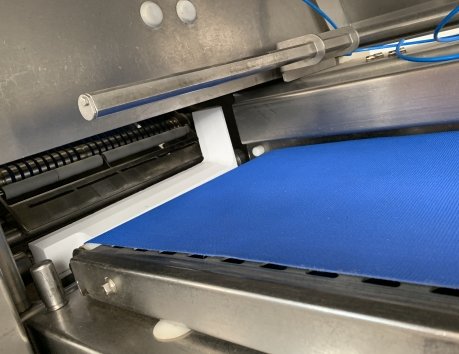

Transfer unit CCU 602 C 10.10.10.010

The transfer unit consists mainly of a portioning conveyor and a control

conveyor. The portioning conveyor picks up the slices cut by the Slicer,

divides them into portions and passes them on to the control conveyor for

further transport to the subsequent units. It is attached to the discharge

side of the Slicer and able to be swung out from the side. The inclination of

the CCU can be set progressively without any tool. The transport means and

the rollers can be easily removed.

CCU standard,

portioning conveyor length approx. 170 mm,

control conveyor length approx. 510 mm.

Portioning conveyor with flat belts,

Control conveyor with round belts.

Slicing bar 602 D 10.10.00.000

Standard execution

Slicing bar horizontal, straight.

Knife head 602 E 60.00.00.000

Circular knifehead HSK 98 0°

Speed increasing ratio 1 : 5,7

Slicing throat 602 F 20.10.00.000

width adjustable up to 360 mm,

height fixed 125 mm

Checkweigher 300 I 30.10.00.100

Digital weighing system with transport speed up to 1,000 mm/s.

Checkweigher completely made of stainless steel.

Tandem checkweigher,

weighing-table length approx. 485 mm, width 2x approx. 180 mm,

capacity up to max. 100 weight measurements/minute

(depending on portions)

max. portion weight 1,000 g,

resolution (precision and display +/- 0,1 g)

weighing-table with round belts.

Rocker 300 K 20.20.00.000

Rocker enclosed in washdown proof stainless steel cabinet

Tandem rocker

length approx. 450 mm, width 2x approx. 200 mm

Execution with flat belts

Transport conveyor CCE 41.20.17.020

Static transport conveyor; heavy version.

Conveyor to transport the portions from the Slicer to the packaging machine.

The conveyor belt can be easily removed from the belt frame without using any

tools. The transport speed is controlled by the Slicer.

Length of transport conveyor, including spanner, approx. 4,100 mm

Table extension of conveyor swinging out,

length of spanner 900 mm, inclinable

Top reject conveyor, length approx. 2,100 mm

Height of conveyors fixed,

Belt-width approx. 420 mm.

Additional increase of the feet SFE 20.00.00.000

For Slicer model SLC.

1 Pc. Weber circular knife WKM 10.10.20.460

Angle, cutting edge 22°

model without teeth

coated, without coated cutting edge.

Diameter 460 mm

1 Pc. Blade guard for Weber circular knife

Blade guard for circular knife of diameter 460 mm

1 Pc. Downholder NH 10.00.00.000

Downholder, spring-loaded

Execution standard with rod

1 Pc. Automatic round grippers for calibrated products ARK 09.00.10.000

for calbre from 96 up to 105 mm

for meat and sausage products

Remark:

Circular knives, Product grippers and Downholders are chosen in accordance

with the original customer's products. For automatic products grippers in

combination with preformed slicing bars an application technology test is

always necessary! The number of grippers results from the applications.