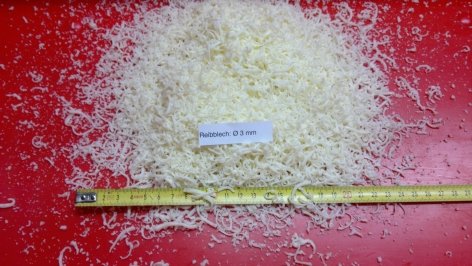

for grating of pre-crushed cheese cubes

Grating Machine TURBO 3000

Machine Description:

The TURBO Grating Machine is for grating of medium-hard cheese e g.

Mozzarella, Swiss-cheese, Edam and Gouda and in special execution also for

Parmesan (not included in this offer). It is a very flexible and powerful

machine and it is easy to clean and to operate. The Turbo 3000 is a heavy

duty built machine and it is designed for the very tough working conditions

when grating cheese cubes. For sure it also fulfills the very high hygienic

requirements of the cheese processing industry.

Basic product::

Cheese cubes (max. 50 mm length of sides)

Product: ?

Final Product:

Grated cheese

Dimension: (must be defined by the customer)

Form: comma-shaped (geometrically non-uniform)

Capacity:

up to 2.000 kg /h with grating drum with hole diameter 3 mm,

valid for semi-hard cheese.

Working method:

The cheese cubes (size max. 50 x 50 x 50 mm) to be grated are filled from

the top into the running grating millwork. By using the centrifugal force,

the cheese is pushed against the grating frame by means of the rotor blades.

The load transmission takes place through a toothed belt from the electric

gear motor to the grating drum, thus preventing a heat transmission from the

driving unit to the grating unit. A decrease of the quality of the grated

product due to penetration of temperature is thereby prevented. A clean

workflow is ensured by the funnel-shaped paneling.

Technical data:

Length: 1.380 mm

Width: 570 mm

Height: 1.900 mm (with base frame)

Electrical connection: 3 x 230/400 V, 50 Hz

Machine execution:

1 grating machine TURBO 3000

(without filling hopper)

CE-conform

incl. following equipment

1 Set grating drum (hole diameter: 3 mm)

1 Base Frame HA-950 mm

Advantages of the TURBO 3000 grating machine:

The use of a tooth belt drive between the electric gear motor and the

grating drum. Therefore there is no heat transmission from the motor into

the grating drum. Especially for cheese with high fat content (like

mozzarella), this ensures a very high quality of the final product.Cover and frame made of stainless steel, material 1.4301 according to the

latest hygienic standards.The infeed funnel on the top of the machine can be easily moved away

(without any tool) and therefore there is free access to the grating drum.

The grating drum can be removed without any tool and it can be easily

cleaned outside of the machine. By moving away the infeed funnel, a safety

circuit is interrupted and the machine cannot be operated in this position.By using the Hajek system with the grating drum and the grating surface,

the shape of the grates looks like homemade.