High Performance circular blade slicer for slicing meat, sausage and cheese

products with excellent slicing quality and slicing performance.

All components on the slicer, from the entrance module to the portioning

unit, have a modular structure and are consistently designed for performance

and excellent slicing quality.

The innovative feeding principle achieves excellent feeding precision with

gentle product handling. This is reflected in unrivalled slice quality and

weight accuracy.

The pioneering hygienic design of the slicer fulfils the highest hygiene

requirements and also allows maximum accessibility.

The tool-free quick-change systems for the application-related accessories

enable extremely short set-up times as well as effective and fast cleaning.

To achieve the best possible slicing results, the product passage height can

be adjusted manually.

Max. slicing height: 170 mm

Max. slicing width: 420 mm

Intuitive machine control with Weber Power Control.

1.2.1 Slicer equipment

1.2.1.1 Basic module

Left hand version (product flow)

- Display mounted on left side

Machine covers made of transparent and impact resistant acryl.

Allows a complete view of the product flow through the slicer

Control cabinet doors made of transparent and impact resistant acryl.

Semi automatic with manual loading up to a product length of 1,200 mm.

Products have to be loaded manually into the slicer from the back side.

Reloading of products during the slicing process is possible

Control panel integrated in the slicer (operator side)

Execution for sausage and ham

1.2.1.2 Without entrance module

1.2.1.3 GripnGo Feeding

One drive for the product grippers.

Multifunctional system combining downhold and product stop function for

reload. Downhold length of 300 mm ensuring a safe grip and feed of products

via lower traction system.

Feeding module for product length up to 1,200 mm

Feeding module in belt execution

End pieces and first cut separation

Basic set-up for active driven traction feed

Fixed product side guiding left

Product side guiding right

1.2.1.3.1 Traction feed cassette

Traction Feed cassette 1 track (GripnGo, VarioGrip) Length 330 mm

Mounting and removal without the use of tools

1.2.1.4 Cutting module

The cutting module cuts slices or pieces from the product log. Its technology

and design are characterized by a kind product handling, a great product

penetration and a flexible adjustment of the blade head in relation to the

product. The result is gentle cutting and exact portioning.

High-performance hygienic circular blade head

for up to 750 revolutions per minute.

The design of the blade head with open housing and no counterweight in front

of the blade is specially designed for applications with the highest

performance and hygiene requirements. The innovative blade head with

integrated counterweight and the Easy Lock blade changing and fastening

system makes it easy to change the blade.

Variable gear ratio for our circular blade head

Downholder basic set-up

3 Pcs.

Downholder swivel drive

For each downholder one swivel drive needed

Classic mounting traverse for the shear edge

1.2.2 Portioning unit

1.2.2.1 Portioning conveyor system

Portioning system basic set-up - standard

Portioning conveyor lowering with stack function, driven by servo motor

max. stacking height: 75 mm

Portion completion

Portion completion is a function to move incomplete portions from the

portioning conveyor to the control conveyor at the end of a slicing

procedure. These portions are returned on the portioning conveyor in order

for them to be completed once the next slicing procedure begins. The portion

is then transferred to the control conveyor for further transport to the

subsequent units.

1.2.2.1.1 Portioning conveyor cassette

Portioning system basic set-up - standard

The transfer unit consists of a portioning conveyor and control conveyor.

The portions will be created on the portioning conveyor. The control conveyor

transfers the created portions to the following unit.

Length: 125 mm

1.2.2.1.2 Control conveyor cassette

Length: 350 mm

Execution with transfer needles

1.3.1 Portion control

1.3.1.1 Checkweigher CCW 500

Digital weighing System for classifying Portion weights according to

applicable package weight legislation and Operator settings.

Accurate weighing results and high reliability are guaranteed by this robust

weighing System, which is perfectly suitable for high demands and harsh

Environments.

The hygienic design of the checkweigher allows for fast and easy cleaning.

Checkweigher CCW 500 basic construction

Basic construction 1-track execution

Incl. 1 weighing table drive and 1 weighing cell

1.3.1.1.1 Weighing table

Weighing table of width 370 mm

Weighing table of length 485 mm

Capacity up to 100 weight measurements per minute (depending on portions)

Max. weight of portion: 3,000 g

1.3.2 Ejection of portion

1.3.2.1 Mono rocker weROCK

Rocker with three possible positions enclosed in a stainless steel cabinet

Single-track execution

Rocker width 375 mm

The rocker stands on its own hygienic feet in the production line.

The hygienic feet meet the special hygienic requirements of the production

environment.

1.3.3 Handing over of portions

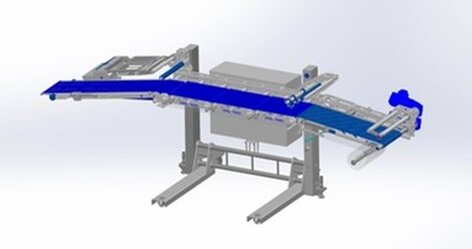

1.3.3.1 Automatic Loader weLOAD 1000

The Automatic loader receives the portions created by upstream

components and puts them into the appropiate die format for the

downstream thermoforming machine.

Depending on the individual application, the product feed times of

the Slicer can be totally or partly compensated by means of the

integrated buffering area, so that the packaging line runs as

continuously and effectively as possible.

Automatic loading of the thermoforming machine is realized by

transmission synchronized with the film indexing chain.

The height of the grouping and buffer conveyor unit, as well as the

angle of the line dividing conveyor, can be continuously adjusted.

This allows the machine to be optimally adapted to the required

conditions.

To access the packaging machine area below the grouping and

buffering area of the Loader, the Loader can be rolled sideways

out of the line.

The power supply is realised via an upstream module

Basic equipment:

- Feeding area with spreading function

- Alignment and groupage of the portions

- Buffering area

Loading conveyor

Falling dirt particles in the thermoforming machine area can be

caught on a film web provided by the customer and fixed in the

retainer and clamping device provided for it.- Gentle-transport functionality enables a smooth and gentle

portion transport through all conveyor units. The speed of the line

and the parameterization of all conveyor units are dynamically adjusted

to the respectively required target throughput, which ensures efficient

running of the whole line.

Please note:

- Depending on product or application characteristics,

manual correction may be required. - Conveyor width 420 mm.

- The maximum diameter of the bottom film reel of the thermoforming

must not exceed 800 mm. - The maximum film width must not exceed 480 mm.

The machine frame stands on rollers. After the supports have been raised,

the Loader can be pushed sideways out of the production line on rollers.

In relation to the product flow, the position of operator

is on the left side of the line.

Line dividing conveyor for applications with line dividing to an identical

number of tracks Portions coming in from the rocker are spread at a distance

between the central axes of the packages and then passed on to the alignment

or grouping conveyor unit

1-track grouping conveyor

Grouping conveyor length 500 mm

2 Pcs. Buffering conveyor

Buffering conveyor length: 500 mm

Upper reject conveyor long version.

Its length ends above the loading conveyor

Catchment tray at the end of the reject conveyor

For collection of rejected portions, thus avoiding them from dropping off

the filled up reject conveyor

Individual conductor labeling

All conductors in the electric control cabinet as well as all pneumatic

components are labeled individually

Additional increase of the feet

The increase mainly consists of spacers in order to

equal irregularities of the floor.

1 Pc. Slicing bar

Standard execution

Slicing bar horizontal, straight

3 Pcs. Downholder

Downholder, pneumatic execution

Metal plate execution, with straight reel 80 mm width

1 Pc. Circular knife

without teeth

coated, without coated cutting edge.

Diameter 430 mm

1 blade guard for Weber circular knife

for weber circular knife of diameter 430 mm

3 Pcs. Automatic round grippers

for product calibre of approx. 100 mm

for meat and sausage products

Weber Remote Service

Machine equipped with industrial router. After activation by the customer

through a VPN connection, access is made via Internet from the machine to

Service Support Portal. Thus, an analog modem is no longer required.

This includes the service provided by the technicians during the currently

regular hotline hours.

Remark:

Product grippers, circular knives and downholders are chosen in accordance

with the original customer's products. For automatic products grippers in

combination with preformed slicing bars an application technology test is

always necessary! The number of grippers results from the applications.