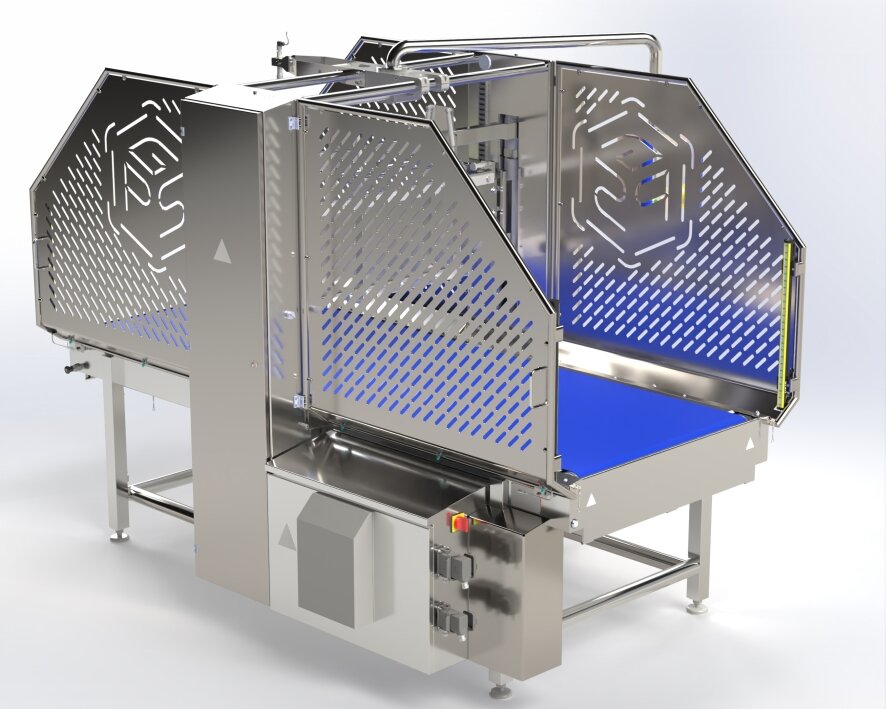

The reisacher ES 1153 Servo Cheese-Cutting machine has been extensively

redesigned and offers a precise and multifunctional solution for cutting

cheese in various formats and configurations.

Equipped with servo-controlled drives in both axes, it guarantees

unconditional performance and is ideal for bar- and portion-cutting.

It easily processes both round cheese wheels and rectangular cheese

blocks and provides particularly efficient handling thanks

to the automatic product adjustment for blocks it makes handling

particularly efficient.

Another ergonomic highlight of the ES 1153 Servo is the integrated

function, which makes unloading the machine even more convenient and

optimizes the workflow. This function not only makes the entire

cutting process more efficient, but also more user-friendly.

The machine is equipped with a powerful drum motor and a cutting belt

that enables a continuous and constant cutting process.

process. The cutting speed can be flexibly adjusted so that both soft and

hard products can be cut without any problems.

In addition, the ES 1153 Servo allows blocks to be divided into variable

product widths, making it ideal for different requirements.

The maximum size for cheese blocks is 800 mm in length and width and

280 mm in height, and round loaves with a diameter of up to 800 mm and a

height of 280 mm can be cut just as efficiently.

Overall, the ES 1153 Servo impresses with a high performance,

ergonomic operation and the ability to customize the cutting process

to the products.

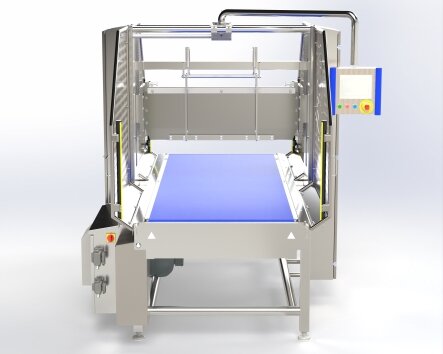

- Machine dimensions: 2,790 mm length, 1,650 mm width, 2,100 mm height

Working height: 830 mm

Product dimensions:

Blocks up to 800 x 800 x 280 mm,

Loaves up to 800 mm diameter and 280 mm height

Cutting types and options:

Block cutting:

The ES 1153 cheese cutting machine is designed for the precise cutting of

rectangular blocks of cheese. The cheese is manually placed on the cutting

belt and the required bar-width is entered via the control panel.

entered via the control panel. The machine cuts fully automatically and

ensures efficient processing. Fixed or automatic cutting of a cheese block

with adjustable start and end cuts.Bar cutting:

The machine enables the cutting of rectangular cheese blocks and round cheese

wheels with a diameter of up to 800 mm into bars. The cheese is manually

placed on the cutting belt and the required width is entered via the control

panel. Due to the drum motor the cutting process is continuous and reliable.Portion cutting:

After cutting into bars, the cheese bars are rotated 90° and placedon the

machine. The machine cuts the bars into portions. This process is carried out

manually and requires the cheese bars to be turned by hand.

Equipment and operation:

The ES 1153 Servo has a robust stainless steel construction (material 1.4301)

with safety covers and protective doors made of acrylic glass. Alternatively

stainless steel safety doors are also available. The machine uses a cutting

belt, which in combination with the drum motor ensures a high cutting speed

and efficiency.

Product configurations can be saved via the intuitive control panel and

quickly retrieved when required. The control system allows adjustment of the

cutting parameters such as first cut, final cut and number of bars and

segments. A light barrier ensures a precise first cut, while the blade

automatically tilts to optimize the cutting result.

Product positioning functions: (optional at extra cost)

Laser positioning device:

A laser projects a X onto the table to facilitate manual positioning of the

cheese. This helps the operator to place the product exactly and minimizes

errors.Mechanically on the knife:

Before slicing, the knife moves to the lower position and the product

is pressed against the blade to adjust it in its orientation.

This enables exact positioning, especially with rectangular formats.

positioning. (Only works in combination with the electric hold-down device)

Result:

The ES 1153 Servo is a powerful and flexible solution for cutting block and

loaf cheese in industrial applications. With the drum motor and the cutting

belt, it provides high efficiency and precision. Due to the optional

extensions such as 3D cutting and a checkout conveyor function with light

barrier, the machine can be adapted to individual requirements.

It is consistently high quality, whether for precise bar cutting,

complex cutting patterns or large production quantities.