Cheese dividing machine

KMS 450

The cheese dividing machine KMS 450 was designed to divide hard and soft cheese into segments or rectangular pieces. The cutting is carried out in one operation with sets of knives or wire cutters. The reisacher KMS 450 cheese dividing machine is the ideal solution for the precise dividing of hard and soft cheese. With its advanced technology and outstanding performance, it enables efficient processing of cheese products. The machine is characterised by its versatile adjustment options, user-friendly operation and high safety standards. The reisacher KMS 450 is the first choice for food manufacturers who place the highest demands on accurate dividing and efficiency.

reisacher KMS 450 - Precise cutting process

The simple design, electromechanical spindle drive, ground guide shafts, oversized bearing and the machine body in hygienic design guarantee long service life and minimum maintenance. The sets of knives include easily replaced single knives made of stainless steel material.

USE & OPERATION:

The cheese dividing machine KMS 450 was designed to divide hard and soft cheese into segments or rectangular pieces. The cutting is carried out in one operation with sets of knives or wire cutters.

The machine‘s design enables the operator to cut up to 3 loaves per minute. For this purpose, the cheese is placed onto the table and the cut is triggered by operating the two-handed control. The set of knives cuts through the cheese. The cut pieces are removed manually and, by pressing the knee switch, the set of knives moves back into the starting position automatically.

Working cycles: approx. 3/min.

SPECIAL DESIGN:

- Designed with conveyor belt. In this design, the cheese is placed on the set of knives and the descending support block presses the cheese through the set of knives onto the conveyor belt. This increases the maximum cyclic output to 4 to 5 loaves per minute.

- Mounted core puncher for punching out the middle core. The core punching tool can be exchanged. The core size is determined by the number of portions. Advantage: Core punching and segment cutting are carried out at the same time in one operational sequence.

- Precise and uniform portioning of hard and soft cheese

- High performance and efficiency in processing

- User-friendly operation and easy handling via two-hand control

- Robust construction for long service life and low maintenance requirements

- Reliable and low-maintenance eletromechanical spindle drive

| Product type | Maximum dimensions | Maximum height |

|---|---|---|

| Loaves | Ø up to 450 mm | up to 250 mm |

| Loaves without core punch |

Ø up to 250 mm | |

| Blocks | up to 450 x 450 mm | up to 250 mm |

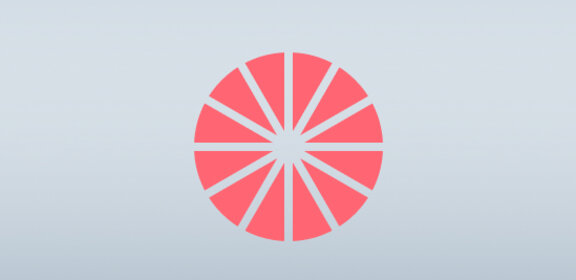

| Number of segments | up to 46 |

| Portion thickness | min. 20 mm |

| Bar width | min. 50 mm |

| Width | 740 mm |

| Length | 840 mm |

| Total height | 1400 mm |

| Electrical connection | 400 V, 50/60 Hz, 3 Ph., N, PE |

| Connection load | min. 2.5 kW, depending on equipment |

- Side-mounted core punch

- Laterally mounted height dividing unit

- Positioning aids or centring units